uPVC window frames, reasons not to install them and the alternatives we prefer…

At Harmonic Design, we’re frequently confronted with the dilemma of balancing the cost to the client with the cost to the environment. Specifying materials which contain plastics, aluminium, steel and concrete are practically unavoidable in some buildings. However, we try to rationalise each decision.

uPVC / plastic is sourced from a range of fossil fuels. As we know, the world currently has more fossil fuel stockpiled (like oil) than it actually needs, but mining companies (like Adani) are pushing to open up new areas to mine fossil fuels; ‘based on demand’.

Fossil fuels are clearly in decline as a primary power source, however big mining companies will push ahead with their fierce mining efforts because ultimately our economic choices are enabling them. uPVC products are among other plastic products helping to drive new demand for fossil fuels. Due to the weak demand for recycled plastic, and since much of the raw material within plastics come from oil and can be sourced from coal, we draw the line at plastic windows!

It tricky to navigate this rationale where on one hand we’re concerned about climate change and yet inadvertently contributing to global heating and degradation of our environment by purchasing “green” products. In consideration of this fact, and due to our research we choose to ‘black-list’ plastic windows ( although our client’s still get the ultimate say :-)

uPVC window frames in Australia have been adopted in part due to their popularity in Europe: “it’s European!” but also due to PassiveHaus increasing the popularity of ‘certified airtight windows’.

Although some local testing has occurred with uPVC products we fear that much like the ‘flammable cladding’, uPVC products are going to be very unpopular in another 10-15 years; if for no other reason than people noticing vinyl-wrap window finishes eventually discolour, crack and peal (looking degraded and requiring replacement).

In our experience you get what you pay for. Other than being thermally effective, many clients opt for uPVC windows because they’re cheap. But given that, we doubt they’ll stand the test of time. uPVC windows are generally manufactured or assembled using 50% to 100% imported materials. With such high embodied energy contained in their production and shipping, any short-term gain will likely lead to long-term pain - for the consumer and the environment.

Aluminium vs uPVC?

To defend uPVC windows some argue that aluminium windows contain more embodied energy than plastic windows. However uPVC windows (especially large sliding doors) actually contain lots of metal reinforcing (steel or aluminium), so to claim that uPVC windows contain far less embodied energy than aluminium ones is convenient at best.

uPVC in the context of building products is hard to remove entirely but in terms of ecology, PVC products are hugely problematic. By way of comparison, we prefer to specify timber windows and yet timber isn’t always suitable so what then? Due to the merits of material reuse and circular economies we’d probably specify Thermally Broken Aluminium (TB-A).

TB-A framing removes the heat transfer that occurs via thermal bridging through aluminum tubing. Whilst TB-A frames are a mix of metal outer and plastic inner, the metal frame is coupled either side of a plastic gusset (thermal break), meaning TB-A frames are easy to dis-assemble AND the metal that’s considered valuable is visible on the outside of the frame.

The economics of redundancy.

Since the iron age, metal has been recycled and redeployed and today scrap-metal is still a booming industry. On the other hand as evidenced by the lack of plastic recycling here in Australia and overseas, plastic is treated as something you throw in the bin.

uPVC window frames have metal reinforcing throughout but it’s hidden on the inside - not good for disassembly.

In both economic value and in terms of logistics, plastic windows are the opposite of Thermally Broken Aluminium. They contain lots of aluminium threaded throughout their plastic shell in which case upon demolition they aren't considered to have any intrinsic recyclable value (because it’s so cheap to source the new raw ingredients from coal or oil). Unfortunately when plastic windows come to the end of their life they will be discarded and neither the aluminum or the plastic components will be returned into their respective supply chains. We just can’t see how there’s enough incentive in Australia for uPVC windows to avoid landfill.

You can turn recycled aluminium cans into windows, but you CAN’T take PET plastic bottles and turn them into window frames -

Footnote about recycling of uPVC: We spoke in detail about all of the above with Australian Window Solutions in response to their direct promotion of their uPVC windows. They’ve said that they use Deceninck extrusions which are sourced from Belgium and that they do use high proportions of recycled PVC. Unfortunately we remain unconvinced that this resolves the issue of collection and reuse of uPVC and plastic in Australia or other parts of the world.

Materials data:

If you want to consider the predominant affect of the materials composition we’ve discussed, you can refer to the Construction Materials Pyramids below where you’ll note that Vinyl (PVC) sits towards the top of all four ‘material’s impact charts’ affecting climate change (global heating).

There are reasons why PVC has been black-listed from use in Green Star rated buildings (accreditation requires demonstration of minimal use of PVC). We’re not saying that TB Aluminium windows are 100% better than PVC. We’re saying that you can’t consider anything in isolation, and when taken in context, including embodied energy, life-cycle, reuse as well as chemical leaching in landfill, uPVC windows are potentially doing more harm than good.

Harmonic Design deeply considers the building materials we choose to specify and as a pathway towards true sustainability we’re motivated to find environmentally ethical solutions so we’ve added plastics to the list of materials that we avoid.

Acidifciation potential (refers to the compounds that are precursors to acid rain)

Eutrophication potential (refers to the impacts on terrestrial and aquatic environments due to over-fertilisation or excess supply of nutrients impacting quality of drinking water, fisheries & recreational water bodies)

Global warming potential (refers to the rise of global temperatures)

Photochemical ozone creation potential (also known as summer smog) refers to emission of substances to air).

Further to above mentioned, PVC has been black-listed from use in Green Star rated buildings (because accreditation requires demonstration of minimal use of PVC). See attached data for reasons why.

These diagrams are inspired by a food pyramid, illustrating what we should consume least at the top of the pyramid.

Image SOURCE: https://materialepyramiden.dk/

Acidification Potential

Eutrophication Potential

Global Warming Potential

Photochemical Ozone creation potential

The New Yankalilla Library Design Concept has been Approved

We’re thrilled that the client working group has approved the interior design concept as an update to the functional layout of the new library. See the fly through below for an interactive preview.

Yankalilla Library Interior Concept Walkthrough Starting at Deck

Yankalilla Library Interior Concept Walkthrough via Main Entry

A regional lifestyle worth the move!

Harmonic Design’s founder & family were featured in The Advertiser, detailing how they (like many others) are reaping the rewards from making the sea change.

Structurally Insulated Panels (SIPs) - What, Why, How and Who

Structurally Insulated Panels (SIPs) are a relatively new method of construction. Popular for some time in the U.S. these panels can be used to build walls, floors and roofs but the terms SIPs describes a sort of hybrid technology. They are a ‘unitised’ building block which fall within the broader category of a ‘sandwich’ panel.

There are many different types of sandwich panels on the market. Typically they’re used in commercial situations like cool-rooms. Until recently in Australia their use in the domestic housing was resigned to prefabricated roofing products like Tridek. However with the increasing demand for high performance housing, sandwich panels & moreover SIPs are increasingly being utilised in the residential sector and this has lead to their uptake in Australia & New Zealand.

The What:

Structurally Insulated Panels (SIPs) are a relatively new method of construction. Popular for some time in the U.S. these panels can be used to build walls, floors and roofs but the term ‘SIP’s’ describes a sort of hybrid technology. They are a ‘unitised’ building block which fall within the broader category of a ‘sandwich’ panel. Sandwich panels have been around for a long time and are commonly used in industrial warehousing or the like to form walls and roofs of large buildings (refer Bondor & Kingspan).

Sandwich panels integrate the cladding, insulation and lining by sandwiching the insulation between the external cladding and the internal lining to make a thickly laminated panel. There are many different types of sandwich panels on the market. Typically they’re used in commercial situations like cool-rooms. Until recently in Australia their use in domestic housing was resigned to prefabricated roofing products like Tridek. However with the increasing demand for high performance housing, sandwich panels & moreover self-supporting ones, known as SIPs are increasingly being used in the residential sector and this has lead to their uptake in Australia & New Zealand.

The Why:

SIP’s have increased in popularity because of their ability to maximise the layer of seamless insulation within the building envelope and if well built should result in an air-tight interior; which in turn will translate to lower energy consumption. There are pros and cons of air-tight buildings which is worthy of further discussion but I’d like to clarify something else about SIPs which is often not explained. That is, SIPs are referred to as ’structurally’ insulated panels (not ‘Integrated’ btw) but the reference to ‘structural’ is easy to confuse. Sandwich panels are typically non-structural, used as a skin suspended over an external frame. Whereas SIP’s are a sort of semi-structural building unit. They are not necessarily structural in their own right but they are at minimum ‘self-supporting’; so if you were to build a box from SIPs it would stand upright but similar to a cardboard box, if you were to apply force to that box (like stepping on it with your foot) it would collapse. This means that although SIPs are used in lieu of a timber frame and although they can span large distances they also have very specific structural limitations and for this reason, beams and lintels are still required to support and carry the load across their openings.

Prior to procuring the construction of my own home using SIP’s, I spent a lot of time trying to understand how they’re best used. This journey to understand SIP’s was difficult as companies who make them ultimately want to maximise sales volume and don’t necessarily explain their limitations. Not to mention that in 2015 when I started researching SIP’s the companies selling them in Oz were mostly reselling product manufactured in the U.S. and so technical representation was ‘light on the ground’.

The How:

It is left to those of us who are designing buildings to determine the suitability of products we specify and my journey to understand SIPs started out with the concept of assembling a house from a flat-packed kit of parts but as I progressed I understood that constructing the shell would be less of an Ikea adventure and more of an expertly built precision exercise that required a highly competent builder. When I advanced to the stage of undertaking construction drawings I began to understand the implications of the term ‘structural’ [in SIP] (as I’ve described above) and how this impacted their intended use for the second floor of our house. Once I realised that the upper floor would require deep beams to support SIP’s larger floor spans, I saw that this would affect the levels of the house requiring an increased height of about 300mm (so not to compromise ceiling height below). This meant that in the house I currently occupy we have SIPs roofing and walling but no SIP’s flooring and instead we used conventional floor framing for the upper storey*.

SIPs are commonly 1200 wide with a variable number of lengths. One way to visualise your design using SIPs is to imagine printing out the architectural drawings of your project, cutting around the edge of each plan & elevation, then placing them onto a board with their edges touching. This would give you a cutting template. If you imagine that template laid over a tiled surface you can visualise the tiles as the units which make up the walls, roof, floor etc. This may be useful to understand how we determine the panels for ordering (although the whole process is vastly more complex than that).

Ready-cut is a service provided by SIPs Industries (WA) who undertake a sort of cut-to-template method. You may consider getting your panels pre-cut like this so that when they come to site they just need to be assembled and that would remove one hurdle of building with SIP’s. Be aware this process attracts a premium (although it may be equal to the labour time of cutting them on site + there are some environmental benefits of the raw materials remaining at the location of manufacture).

As a Building Designer I became determined to understand how many panels we needed to order for our house. To that end I produced a 3D modelling component which allowed me to array the panels along the building form and to schedule the required quantity and sizes of panels. I’m happy to now offer this as an additional service provided by Harmonic Design.

The Who:

SIPs are a specialist building material, trade & methodology. For that reason you’re best to look for people who understand them and who have experience with them. For those reasons they do attract somewhat of a premium in terms of their installation although there are some builders who will work with them directly and other builders who will employ sub contractors to install them.

Don’t expect much love from structural engineers either. Unless they’ve worked with the SIP system before they probably have no idea how they work. The subtleties of the system cannot be easily understood from installation guides or construction manuals. Insulspan have lots of details and videos online which help to guide designers and builders. Their product is exported from the U.S. as discussed further down.

Some info about various parties who I had dealings with whilst trying to procure our house in Normanville:…..

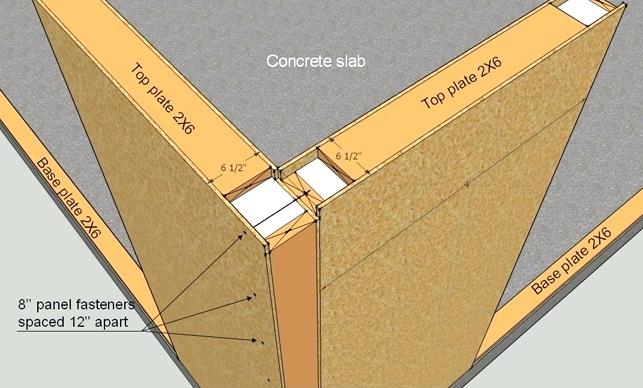

SIPS industries

In 2017 after a working with other companies we sourced the panels through these guys. They're the most cost effective that I have found and will easily give you a ‘supply only cost’ of the panels you need which will help you to budget. They offer their pre-cut design service but their price will possibly double for that. Their details are quite good although they’re not as pretty as the Insulspan one’s. You can see the use of the splines (studs) everywhere in their details which is a good representation of the built result - ie there’s still plenty of studwork required. Studs at corners, panel joins (some) window inserts (if a lintel isn’t required) + top and bottom plates, etc.

http://www.sipsindustries.com/about/downloads/

Structural Panels Australia (Associated with Tridek Roofing)

These guys were still developing their SIP’s business when I went to them initially (Seems like they expanded from Tridek). They were very helpful initially but failed to back up their sales pitch when I went looking for tech help. Having said that I would take a second look at them because they’re offering an alternative to EPS foam core which is what I was initially trying to get hold of - PUR - because it is more eco’ friendly than EPS core (read note about EPS further down).

http://structuralpanels.com.au/products/

Their tech details are quite good also but still hard to garner how the system works in reality. Eg, you can’t easily use panels as flooring if you’re doing a big span (like I have done). You practically need a post and bearer system if you’re going to do the floor with panels - still possible but you need a deeper floor section than typical - which I didn’t want so I went back to using joists for the first floor.

Fenster & Panel

These guys were very helpful for the most part but seem to want to build rather than supply. I got a lot of info from them but after they did all that they didn’t seem to want to give me a panel-only supply quotation which is probably because they were importing their panels from the U.S. at a premium. They import Insulspan panels.

http://fensterandpanel.com.au/links/

Insulspan

Insulspan’s website is fantastic and has a lot of links and general info - however if you don’t intend to become a building designer, architect or builder, I wouldn’t bother with all the technical discussion - leave it to the professionals.

http://www.insulspan.com/product_specs/product_bulletins.aspx

QikFitFloors - An alternative pre-fab flooring system:

I would honestly consider using this system (or another mob) for a ground floor install if you’re not doing a slab. I did however struggle to get a quote from them, perhaps because my project was in SA though.

http://www.qikfitfloors.com.au/wp-content/uploads/2014/03/QitFit-Instruction-Manual.pdf

The Summary:

There are various pro’s & con’s of using SIP’s as discussed on other forums. I’d suggest you cannot do too much research however I’m happy to provide a broad testimonial for SIPs and advocate their use. Not only do they have thermal benefits but like Strawbale they also have acoustic benefits and seem to provide an excellent level of resonance (in the case of our Normanville Residence I also exposed much of the OSB lining as a design feature which probably improved the acoustics). If like me you are looking for a high level of thermal comfort to be delivered by continuous insulation but aren’t in a position to use a method like Strawbale or Hempcrete, SIP’s may be an appropriate solution.

Finally, a note about EPS foam-cores within SIPs . If you’re an environmentalist (like me) you may struggle with this material. A reality of EPS is that although it’s ‘non-toxic’ it is still a troublesome pollutant. EPS has many applications in construction from slab insulation through to everything that comes to site packaged in the stuff (polystyrene). Unfortunately even if you have a tidy builder, EPS wastage from the panels being ‘worked’ onsite, off-cuts will find their way into your immediate environment. So I’d strongly advise sourcing PUR or PIR foam based panels because of the environmental dilemmas we face with EPS. Yes - we used EPS to construct our own house but I’m troubled by this. The problems associated with EPS have increased since the recycling crisis of 2016/17 which has impacted recycling streams world-wide. It is now much harder to recycle EPS in Australia than it was and this means more waste is going to land fill.

Ideally we’d all source PUR foam panels instead of EPS!

_________________

*Adding SIPs for a floor suspended above ground also tends to increase the complexity of the build due to plumbing, waterproofing of wet areas, wiring etc.

Harmonic Design will be happy to consult on your next design / build.

Featured Posts

Lachie is a warm and knowledgeable building designer who started his own company – Harmonic Design – in 2019, from the studio space at his Japandi (Japanese/Scadanavian) inspired home in Normanville.

Born in 1979, the son of a language teacher and a journalist, he had a family that fostered his creativity and love of technology and design from a young age.